As Your Partner for What’s Next, TEAM Technologies leverages our decades of combined expertise in product development, materials, and manufacturing to continually improve time to market and, ultimately, the lives of patients and those who care for them.

At TEAM Technologies, we strive every day to fulfill our mission of Helping Those Who Help Others by realizing that every product is an opportunity to change a life. That’s why we remain dedicated to providing unique and cutting-edge solutions that help in the development of industry-leading wound care products.

Wound Care Solutions

Engineering and Design

Whether you have a fully engineered prototype or a new product idea, TEAM Technologies’ engineers can provide the expertise required to develop high-quality, life-changing wound care products. With an innovative approach to project management, we enable our customers to seamlessly go from concept to commercialization faster and more efficiently.

Prototyping

A strong prototype lays the foundation for a viable wound care product. That’s why we have a fully equipped Solutions Lab dedicated to rapid prototyping and development of pilot production processes. Explore product designs, test alternative materials, and refine production techniques alongside our experts to help reduce costs and eliminate stopgaps throughout the production process.

Wet & Dry Chemistry

Contained within one of our ISO 14644-1 Class 8 Cleanrooms, TEAM Technologies has complex wet and dry chemistry capabilities needed to develop advanced wound care products, including those that contain antimicrobial properties. Our capabilities include: accurate measuring of dry chemicals using a fume hood system, cold storage, reverse osmosis water systems, full QA lab testing and finished product testing, and humidity-controlled drying rooms.

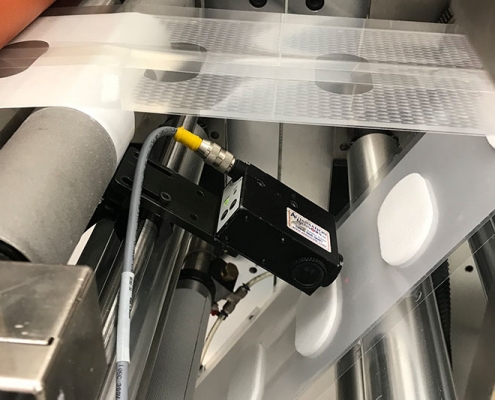

Converting

TEAM Technologies is an industry leader in the intricate, multi-part lamination and rotary die cutting of specialty materials, including high MVTR films, absorptive foams, wicking layers, medically approved soft silicone adhesives & acrylic adhesive systems, and other specialty materials. We offer a variety of unique capabilities ranging from island placement, precision die-cutting, roll-to-roll laser cutting, and automated final component packaging and assembly.

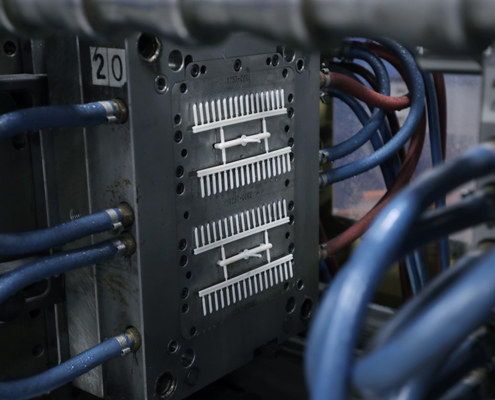

Injection Molding

Whether you need custom prototype molds or large-scale finished wound care products, TEAM Technologies’ state-of-the-art equipment and advanced methodologies allow us to fabricate custom plastic parts that meet the precise tolerances and protocols needed for your wound care products.

Materials Knowledge

TEAM Technologies works with thousands of advanced materials and maintains strong relationships with leading suppliers to provide customers with the most effective, high-quality wound care solutions. Our stick-to-skin adhesive expertise covers the full range of applications and needs, including hypoallergenic, low-trauma, repeat insult, length of wear, weight supporting capacity, and sterilization compatibility.

Packaging and Fulfillment

As an end-to-end strategic partner, TEAM Technologies meets our customers’ needs all the way through to packaging and fulfillment. Form, fill, and seal pouching in ISO 14644-1 Class 7 and 8 cleanroom environments ensure medically validated packaging. Our inventory management services ‒ coupled with the boxing, coding, and packing of your finished products ‒ reduce your costs and ensure your wound care products are available where and when you need them.

Contact Us

About TEAM Technologies

TEAM Technologies is a leading end-to-end manufacturing solutions provider for medical and dental products. From conceptualization to completion, TEAM Technologies offers the technology and solutions for every stage of the development and manufacturing processes all under ISO 13485 and FDA regulated guidelines. TEAM Technologies’ decades of experience mean our partners can be confident products will exceed the industry’s highest quality and specification standards while being delivered on time and within budget.