Your Partner for What's Next.

We’re committed to helping those who help others by manufacturing stick-to-skin and wearable medical product solutions that help to change patients’ lives.

80+ Years

Coast to Coast

Global Locations

Material Selection

Engineering and Design

We partner with innovative healthcare companies to take high quality, life-changing medical products from idea to market seamlessly and cost effectively. Our decades of proven expertise, efficient project management, and state-of-the-art manufacturing capabilities ensure that our partners remain on the cutting edge of the medical industry.

- ISO 13485

- ISO 9001

- FDA Regulated

- MDSAP Certified

- Class 7 & Class 8 Cleanrooms

SPECIALIZED MATERIALS EXPERIENCE

Adhesives

Films & Plastics

Foams & Elastics

Specialty Materials

Prototyping

Unlike many other manufacturers, we have a fully equipped Solutions Lab dedicated to rapid prototyping and processes in place to plan for long-term Design for Manufacturability (DFM). Explore product designs, test alternative materials, and refine production techniques alongside our experts.

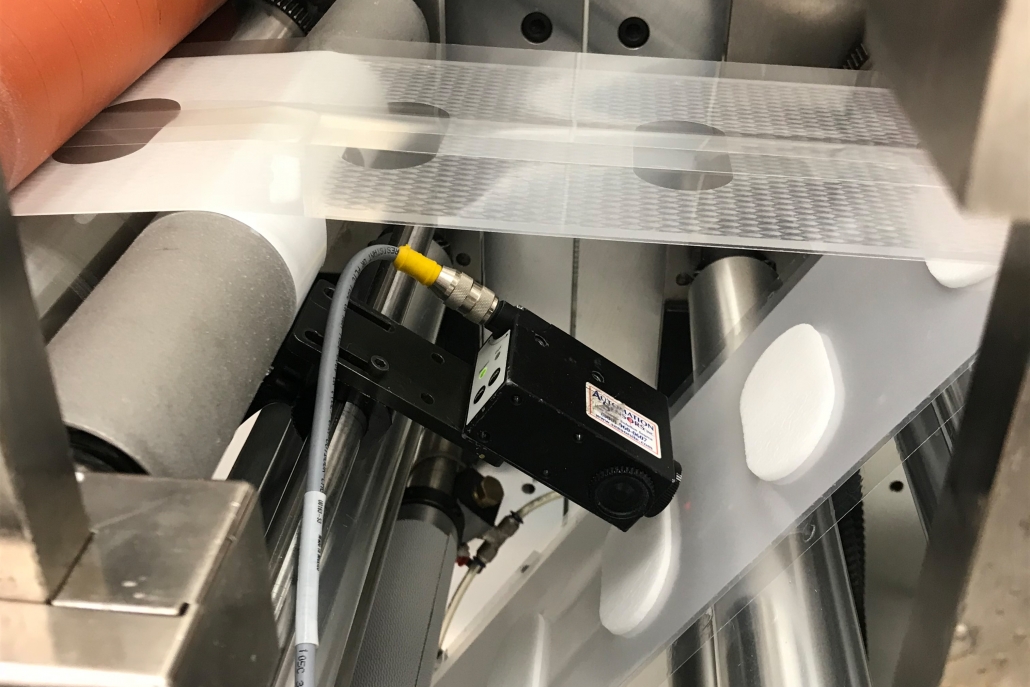

Converting

As an industry leader in medical converting technology which includes intricate, multi-part lamination and die cutting operations, we offer a wide range of unique capabilities for the precision cutting of specialty materials, including adhesive coated films and fabrics, and other specialty membranes, plastics, and materials.

Injection Molding

From custom molds for prototypes to large-scale finished products, our state-of-the-art equipment allows us to fabricate custom plastic parts that meet the precise tolerances needed for stick-to-skin and wearable medical product solutions. With our recently expanded ISO 8 Cleanroom at TEAM Technologies’ Batavia Operations, you can depend on TEAM as a partner whether you need a single molded component, sub-assembly component or finished device.

Materials Knowledge

Our deep industry knowledge of advanced materials and

strong relationships with leading suppliers means we can provide the best solutions for each customer’s unique needs. Our expertise covers the full range of applications including: hypoallergenic, low-trauma, length of wear, weight supporting capacity, and sterilization compatibility. And as a 3M Preferred Converter, TEAM Technologies has access to the highest quality materials.

Packaging and Fulfillment

As an end-to-end strategic partner, TEAM Technologies delivers on customers’ needs for high-speed, custom packaging and fulfillment. Our inventory-management services can save you time and money and simplify your supply chain so you know your product is reaching the right people at the right time.